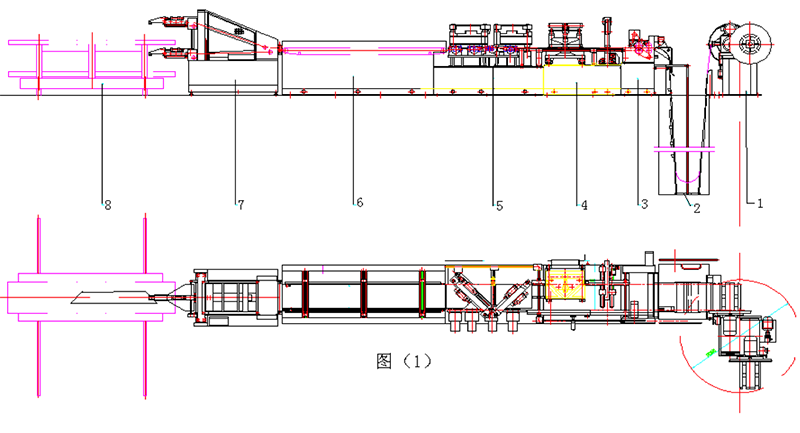

Cut to length line

1. Double head de-coiler 2. Sheet guiding device 3. Sheet feeder4. Punching unit 5. Shearing unit 6. Discharge table

7. Diverting mechanism 8. Stacking trolley

GENERAL

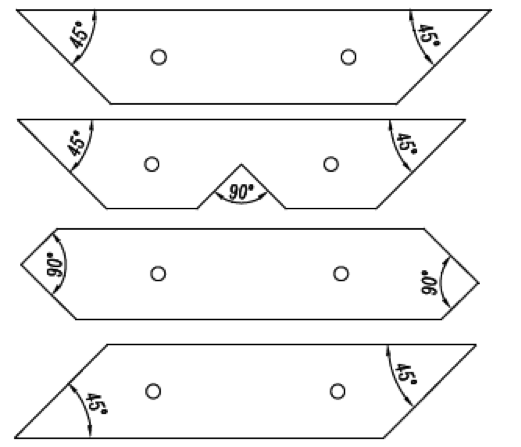

Type Cut-to-length line for transformer lamination is the special equipment for transformer lamination manufacturing. This is our new generation of cut-to-length line. The line is used to punch and shear sheets of small-medium all oblique joint core, including side leg sheets, the yoke and central leg sheets. The silicon steel coil is punched and sheared to be certain shape and size of laminations, then be diverted and tidied in order to use in stacking. The main sheet shapes could refer to the following lamination drawing (see Appendix1).

The advanced control system is adopted to make sure accurate and stable operation. Embedded operating terminal is easy to complete parameter input.

THE MACHINE CONSISTS OF:

| Hydraulic Double Head Decoiler | 1 set |

| Sheet Guiding Device (with buffer pit) | 1 set |

| Sheet Feeder | 1 set |

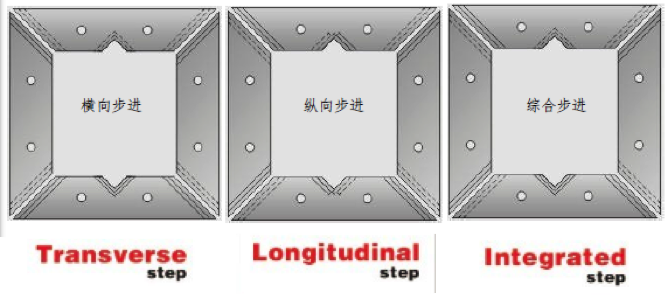

| V-Notch Punching Unit with Motor Driven and Cross step-lap mechanism | 1 set |

| Hole Punching Unit with Motor Driven and 2sets dies(buyer supply sizes) | 1 set |

| Shearing Unit with Motor Driven (45° and 135°) | 2 sets |

| Discharge Table | 1 set |

| Diverting Mechanism | 1 set |

| Electrical Control System (control cabinet and operation) | 1 set |

| Pneumatic system (not including air compressor and decontamination plant) | 1 set |

MAIN TECHNICAL PARAMETER

The requirement for the steel sheet coil, as follows:

| Material | Grain Oriented electrical silicon steel sheet (Reference to international requirements) |

| Thickness of sheet | 0.23~0.35mm |

| Sheet width tolerance | ± 0.1mm |

| Edge camber | ≤0.1mm/1000mm |

| Burr | ≤0.03mm |

| Wave factor | ≤15mm/1000mm (The wave height shall be less than 15mm in a length bigger than 1000mm) |

The requirement for the supply, as follows:

| Power | 35 KW, AC380V±10% (3-phase), 50Hz±2%; AC220V±10% (1-phase), 50Hz±2%; |

| Compressed air | Pressure ≥ 0.7 MPa, Dew point ≤ -40℃, Oil content ≤ 0.01 PPM Consumption~ 1.6 m3/min |

| Temperature | 5~40℃ |

| Humidity | ≤85% |

| Buffer pit | By the buyer |

| Foundation | By the buyer |

Processing range

| Width of sheet | 40-450mm |

| Length of sheet | 300-2500mm |

| Thickness of sheet | 0.23-0.35mm |

| Accuracy of cutting length | ±0.1mm |

| Shearing burr: | ≤0.02 mm |

| Accuracy of cutting angle | ±0.01° |

| Feeding speed | 240m/min |

| Internal diameter of coil | 470-520mm |

| Max. load of each mandrel | ≤2T |

| Diameter of punching hole | Customized |

| Hole punching burr | ≤0.02 mm |

| Control system | PLC + Touch screen |

Stepping

REFERENCE LAMINATION DRAWING